A Changing Workforce

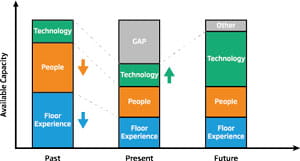

Figure 1: Closing the Qualification Gap

For years, there has been warnings about the upcoming increase of workforce retirements. The phrase, the silver tsunami, is used to describe the movement of the Baby Boomers Generation (those born in between 1946-1964) as they head into their retirement. There are approximately 72 million baby boomers and more than half of the first-year boomers have retired. Every day, 10,000 boomers reach retirement age.

As the U.S. deals with an aging population, manufacturing industry is a disproportionate disadvantage — the age gap between the manufacturing and the non-farm workforce have widened.

The graphics in Figure 1 shows where we came from, where we are today, and how companies are filling the gaps.

Technology is increasingly being deployed to provide redundancy and backup support to maintenance teams to ensure continuous operations.

Powered by Nederman Insight

Changing Technology

Industrial plants are constantly developing — Evolving to maximize the availability and reliability of their equipment.

The term Industry 4.0 (Industrie 4.0) is generally used to describe the fourth industrial revolution. What is the fourth industrial revolution? Following the third industrial revolution (computer and automation) that occurred in the late 20th century, Industry 4.0 introduces Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT) technologies across a broad range of industries.

The combination of cuber-physical systems, the Internet of Things, cloud computing and cognitive computing makes the reality of smart factories possible. As a result, factories are reporting reduced equipment downtime, increased product quality and a safer work environment.

Bridging the Gap

How? With MikroPul-Assist.

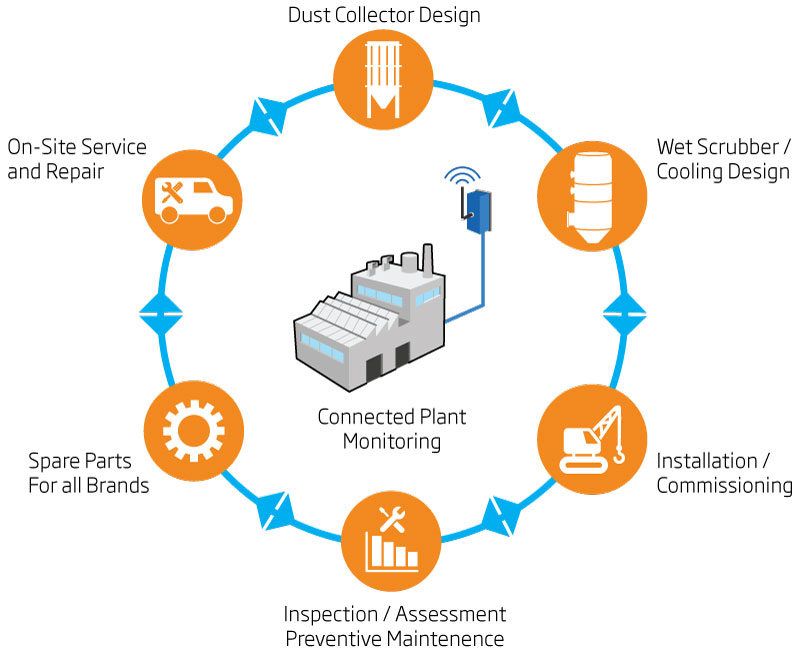

Figure 2: Connected Plant Monitoring

MikroPul-Assist is our remote monitoring technology supported by expert MikroPul technicians. The platform helps industrial plants, and maintenance personnel reduces downtime on critical processes, while predicting potential filter performance issues.

With MikroPul-Assist, new and existing customers can see critical, real-time performance parameters graphically displayed on a dashboard powered by the Nederman Insights cloud-base application. Using the data, trained technicians can monitor and inform owners when action is needed to ensure continued and efficient functionality.

"Nederman MikroPul is the go-to provider for the design, development, fabrication and maintenance of industrial dust collectors. MikroPul-Assist gives our customers a corner-stone of information that improves reliability, uptime and performance."

-Alan Traylor, VP of Business Development, MikroPul

MikroPul-Assist is the ideal collaboration of human and machine working together to improve uptime, mitigate risk, and save money.

All filters can be retrofitted with MikroPul-Assist. Beyond the basic sensor measurements, additional sensors are available to capture other relevant performance data and customers may opt for in-person visits for total confidence in long-term system health.

MikroPul-Assist can solve problems like these:

- Emergency situations in the plant, i.e. stop production or fire

- Unable to plan maintenance task with enough advance notice

- Unscheduled downtime due to equipment failure

- Difficulty in finding new employees with the right experience and skills

Added Benefits:

- Communicate to Business Leaders that all processes are in control

- Achieve savings from the maintenance budget

- Take care of maintenance employees' commitment to overtime or off-hours

- Have a stable and reliable service and maintenance partner who handles every need