- Home

- Products

- Wet Scrubbers

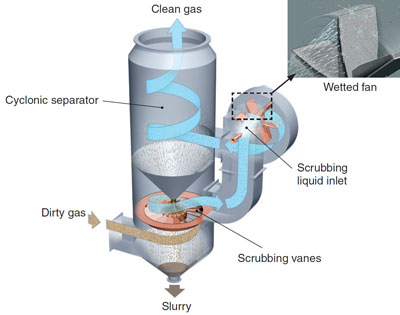

Dynamic Scrubber with integral wetted fan

Dynamic Scrubber

This scrubber solves air pollution control problems in general industrial applications, particularly in mining, minerals and ore operations.

MikroPul’s flexible designs are well suited to solving problems across multiple industries. The Dynamic Scrubber can be used in all industrial applications where dust, aerosol, and gas are present. It can also be used for dust control in spray drying and incineration plants and for odor control. This scrubber offers a more compact system than other scrubber designs due to its integral wetted fan.

Operation

Dust laden gas enters the lower chamber of the scrubber tangentially, imparting a cyclonic separation action to the stream. Coarse particles are removed by a combination of centrifugal and gravitational forces. The stream encounters slurry, created in a later stage, coming down from the upper chamber, and becomes partially wetted, initiating agglomeration.

As the stream spins through a series of scrubber vanes, intermediate sized particles impinge on the wetted surfaces of the vanes. These particles are then washed down. The gas stream containing the remaining fine dust is drawn into an adjacent chamber containing a fan. Atomized scrubbing liquid is sprayed into the eye of the fan, further reducing droplet size. These droplets encapsulate the fine dust particles, thus enhancing agglomeration.

The gas stream then flows into the upper chamber tangentially at high velocity. The wet agglomerated particles are forced by cyclonic action against the chamber walls and drain down to the internal discharge cone. The gas stream, free of liquid droplets, spins out through an outlet atop the scrubber.

Benefits

- High collection efficiency of solid and gaseous pollutants

- Maximum pressure drop of 1.2 kPa (5 in. w.g.)

- Multiple scrubbing stages can be applied

- Various mist eliminator devices can be utilized

Sample Applications

- Mining- Uranium and non-ferrous ores such as Copper and Zinc

- Minerals- Potash

- Lime kilns

- Lime shakers

- Dissolving tanks

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.