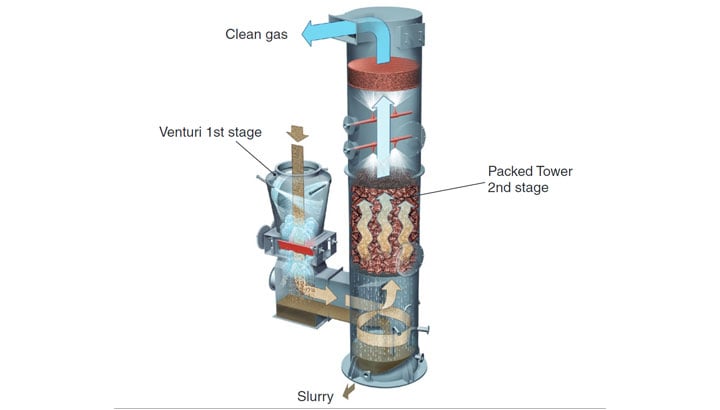

Wet Scrubbers

We can optimize wet scrubber performance and design for your application which can achieve > 99% efficiency. Our wet scrubbers can be configured to meet your requirements and are available in mild steel, FRP, or stainless steel.

Nederman MikroPul has been a pioneer worldwide in providing wet scrubbers to solve air pollution control problems for almost 50 years. We offer designs to meet almost any requirement — in several configurations and a full range of sizes. Numerous materials of construction include carbon steel, plastics/FRP, and exotic alloy steels. Nederman MikroPul has the demonstrated capability to engineer a wet scrubber system that efficiently meets your needs.