- Home

- Products

- Gas Cooling

Cooler KU

Cooler KU

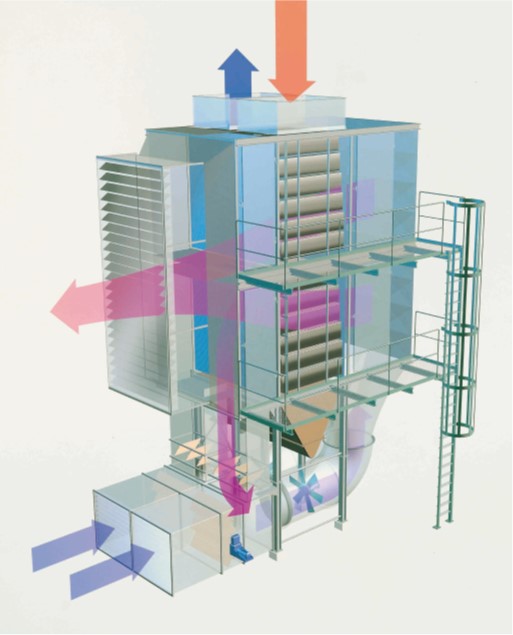

The hot gases flow into the cooler vertically downwards along the cooling elements. The gases are deflected through 180° and a pre-separation of the coarse dust takes place.

Why do I need a gas cooler or heat exchanger before my fabric filter?

An industrial process that creates heated gas can be hazardous for the downstream ductwork or for the filter. Heated dust particles can cause fires that may be hard to detect if temperatures build up slowly and/or there is no temperature sensing built in. Either duct fires, filter bag fires or internal filter fires will stop the production process and recovery and repair may be very expensive.

How can I protect against the effects of corrosive gases in my industrial process?

Many operations, including the melting of Aluminum, produce corrosive gases such as SO₂. Also high humidity can cause acidic condensates such as HCl. By using a gas cooler with internal heating, the producer can avoid damaging condensates in the gas through precise control of the inlet gas temperature. Then the cooled gas does not transition below the dewpoint temperature.

How does a gas cooler improve the efficiency of dust collection/ filtration?

By deflecting hot gases downward and then through a 180 degree path the model KU cooler delivers a level of pre-separation for coarse dust particles, directing smaller particles to the fabric filter media

How easy is a model KU gas cooler to maintain?

The model KU is a compact design that is easy to access. By removing condensation and pre-separating large particles it reduces stress on its internal components and reduces service costs.

How can I meet my sustainability goals using heat exchangers?

Heat exchangers such as the model KU can include systems to provide heat to the internal environment to supplement or replace the use of fossil fuels. The heated medium can be air, water, steam or oil.

Model KU gas coolers produce no waste water materials that might have an environmental impact.

The model KU design is compact, saving valuable production space.

How does the model KU Gas Cooler work?

A partial flow of heated cooling air and fresh air are sucked in together from the cooling air fan. A pre-selected mixing temperature is regulated prior to entry into the cooling elements by opening or closing the fresh-air valve. This means some of the process air is recycled to control inlet air temperature at a target value.

Benefits of our Gas Coolers

- Handles temperatures up to 600C (1,112F).

- Automatic Cleaning system for sticky dusts

- All elements accessed from the catwalk

- Ability to pre-heat cooling air to eliminate condensation issues

- Low-profile and compact

- No Fluids Needed

- Self Cleaning Option

- Customizable

- Small Footprint

- Fully Automatic Operation

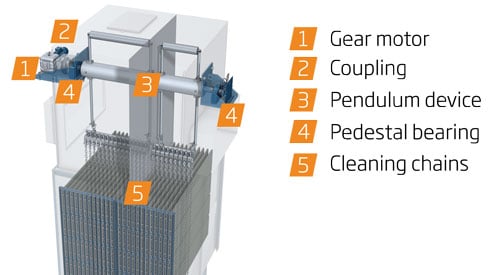

Cooler Cleaning

The cooling elements are designed so, that the cooler cannot become clogged up with dust. An automatic cleaning device is installed for sticky dust.

How the cleaning system works

A pendulum device with cleaning chains is moved by a gear motor from one side of the hood to the other. The cleaning chains scrape adhering dust off the cooling elements.

The parking time depends on the type of dust and the dust content in the polluted process gas. The path of the chain holder is limited by two proximity switches.

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.