- Home

- Products

- Gas Cooling

Cooler KS

Cooler KS

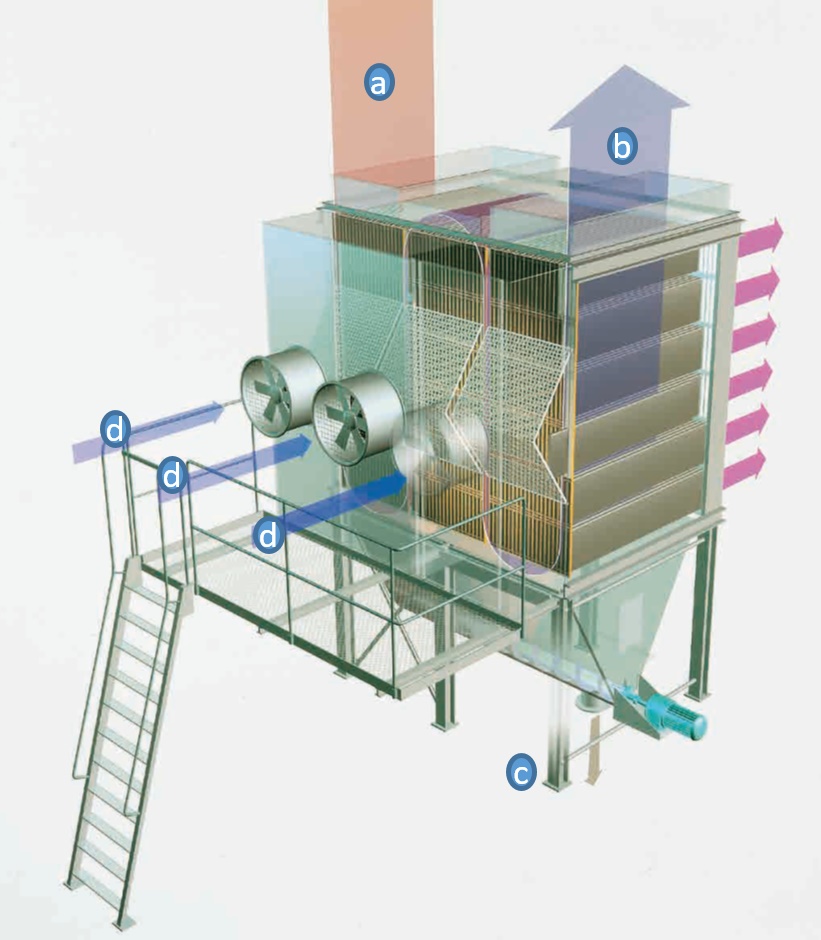

Cold air fans suck cold air out of the environment and transport it crossways to the hot-gas flow through the cooling elements. A temperature control element switches the necessary number of cold air fans on.

A Cassette-type heat exchanger/gas cooler with pre-heating of cooling air up to 600C (1,112F). The cooling air must be preheated if there is any risk of the temperature on the cooling elements dropping below the acid dew point when cooling hot process gases.

Why do I need a gas cooler or heat exchanger before my fabric filter?

An industrial process that creates heated gas can be hazardous for the downstream ductwork or for the filter. Heated dust particles can cause fires that may be hard to detect if temperatures build up slowly and/or there is no temperature sensing built in. Either duct fires, filter bag fires or internal filter fires will stop the production process and recovery and repair may be very expensive.

How can I protect against the effects of corrosive gases in my industrial process?

Many operations, including the melting of Aluminum, produce corrosive gases such as SO₂. Also high humidity can cause acidic condensates such as HCl. By using a gas cooler with internal heating, the producer can avoid damaging condensates in the gas through precise control of the inlet gas temperature. Then the cooled gas does not transition below the dewpoint temperature.

- a. Dirty gas intake

- b. Dirty gas outlet

- c. Dust outlet

- d. Cooling air intake

Benefits

- Cooling of hot process gases up to 600°C

- Modular design

- Heat recovery

- Reliability

- Low maintenance

- Easy to exchange cooling elements

- Leak-proof welded construction

- With cooler cleaning for sticky dust

- Short assembly times =low assembly costs

Cooler Cleaning

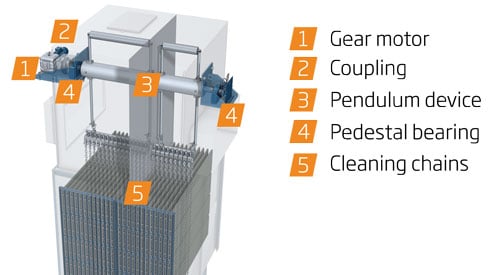

The cooling elements are designed so, that the cooler cannot become clogged up with dust. An automatic cleaning device is installed for sticky dust.

How the cleaning system works

A pendulum device with cleaning chains is moved by a gear motor from one side of the hood to the other. The cleaning chains scrape adhering dust off the cooling elements.

The parking time depends on the type of dust and the dust content in the polluted process gas. The path of the chain holder is limited by two proximity switches.

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.