- Home

- Products

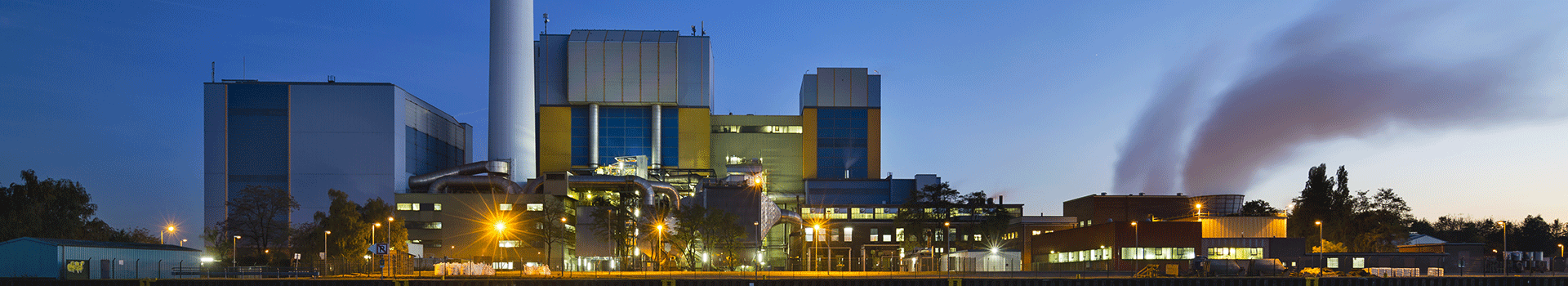

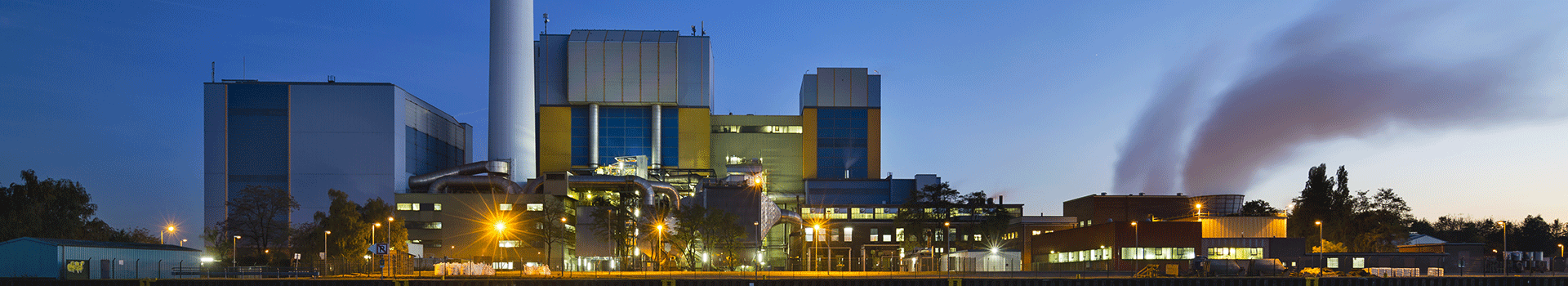

- Exhaust Gas Cleaning

Adsorption with activated carbon

Adsorption with activated carbon

Both mercury and dioxins and furans can be adsorbed with activated carbon (AC) and then separated from the exhaust gas.

These powdery sorbents are added to the exhaust gas flow and separated together with the dust-like pollutants in the fabric filter.

The efficiency of the separation increases as the exhaust gas temperature decreases.

If the pollutant separation takes place at a high temperature level (e.g. 230°C) due to the use of catalytic filter media, a separate sorption stage with an additional fabric filter must be installed downstream, depending on the required mercury removal efficiency. The required sorption temperature is set by an interposed heat exchanger.

KEY ADVANTAGES OF ADSORPTION WITH ACTIVATED CARBON

- Simple integration into the various processes for separating acidic pollutant gases

- Very simple system with only a few components (storage and conveying)

- Proven technology with a long track-record of success in the industry

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.