- Home

- Products

- Wet Scrubbers

Mikro-Vane Scrubber

Mikro-Vane Scrubber

This basic scrubber has the capability of tolerating high inlet dust loadings without sacrificing its collection efficiency, which is 99+% at around the 5 micron size range.

Operation

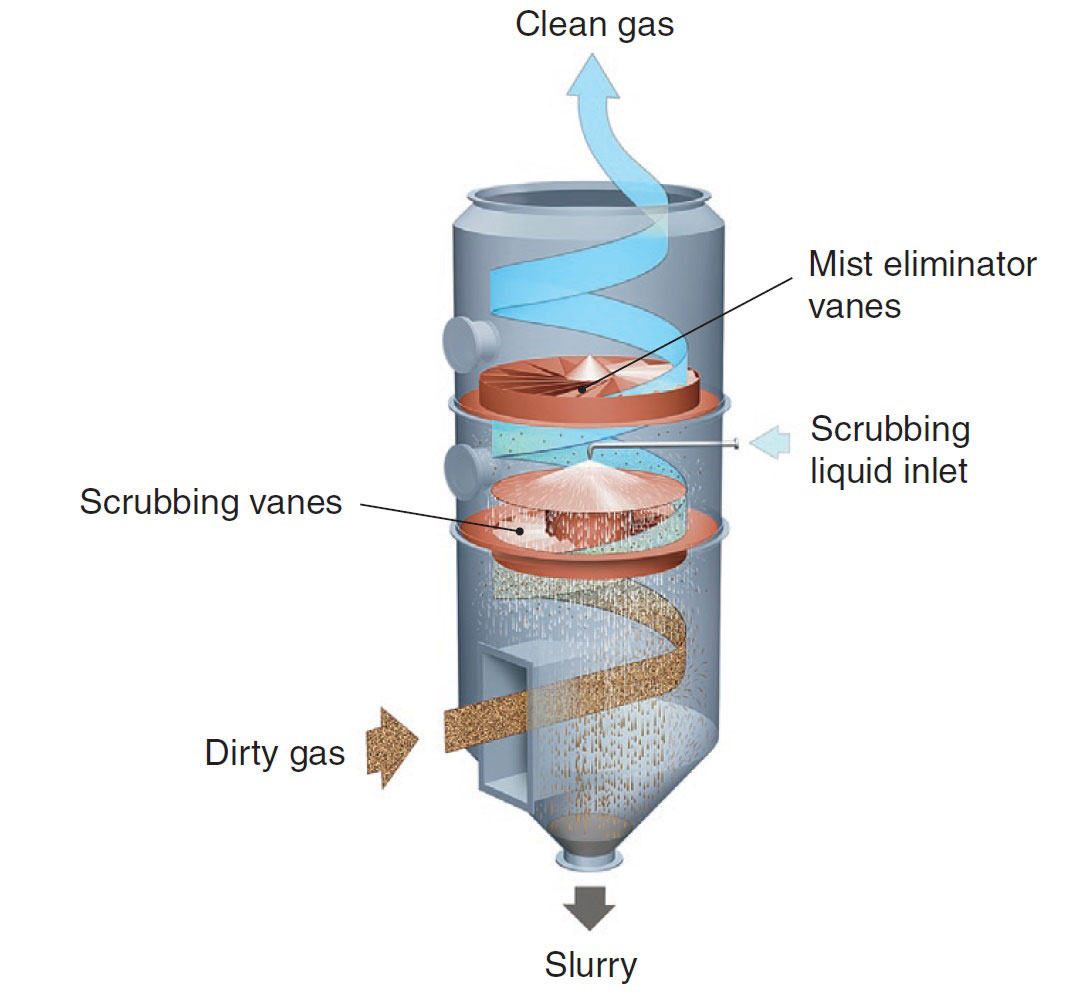

Scrubbing liquid is introduced into the scrubber as a spray directed down over a circular “scrubbing vane” arrangement. As the liquid drains through the vanes, it creates curtains of scrubbing liquid. Dust laden gas enters the scrubber tangentially and collides with the curtains initiating particle agglomeration. The coarser particles produced are washed down to the slurry outlet. A restriction disc located in the scrubbing vane assembly accelerates the spin velocity of the gas.

This action combined with the flood of atomized liquid from the spray causes the formation of fine liquid droplets which encapsulate the fine particulates, again enhancing agglomeration. The cyclonic action of the saturated gas stream as it spins upward forces the agglomerated particles to fall out of suspension. The coarser droplets impinge on the mist eliminator vanes and the finer droplets are forced to drop out of suspension by gravitational and centrifugal forces acting on the gas stream as it exits through the top.

Benefits

- Handles high dust loads

- Low pressure drop - 1.2 kPa (5 in. w.g.)

- Low water use

- Low water pressure

- High solids content in recycling water

- No moving parts

- Low maintenance

Sample Applications

- Dryers

- General dedusting

- Mining

- Polypropylene dryers

Contact us to create your custom solution

Call us at: 704-399-7441 or fill out the form below.